Need help finding the right size? Start here.

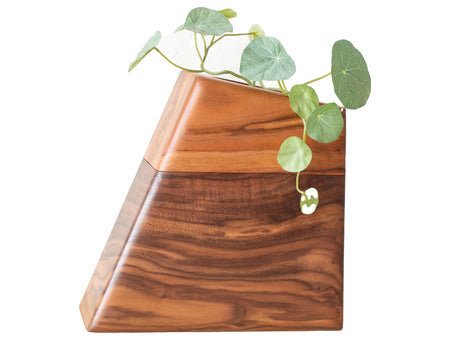

How do Planturns work?

No tools required

It couldn't be easier. Cremains are securely housed in the bottom as the plant sits in the solid wood top. Held together by rare earth magnets.

Let customers speak for us

Looking for something different?

We love doing custom orders! Our designer will work closely with you to create a beautiful and one-of-a-kind keepsake.